English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

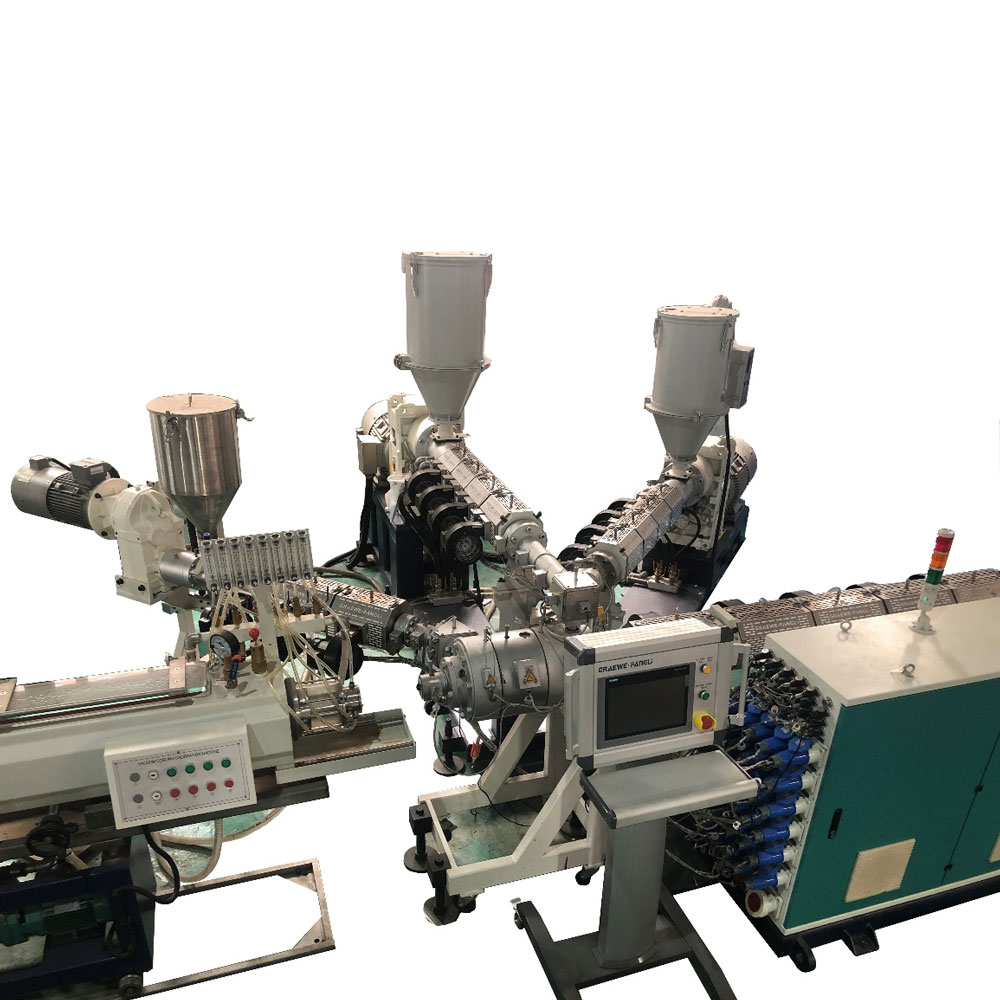

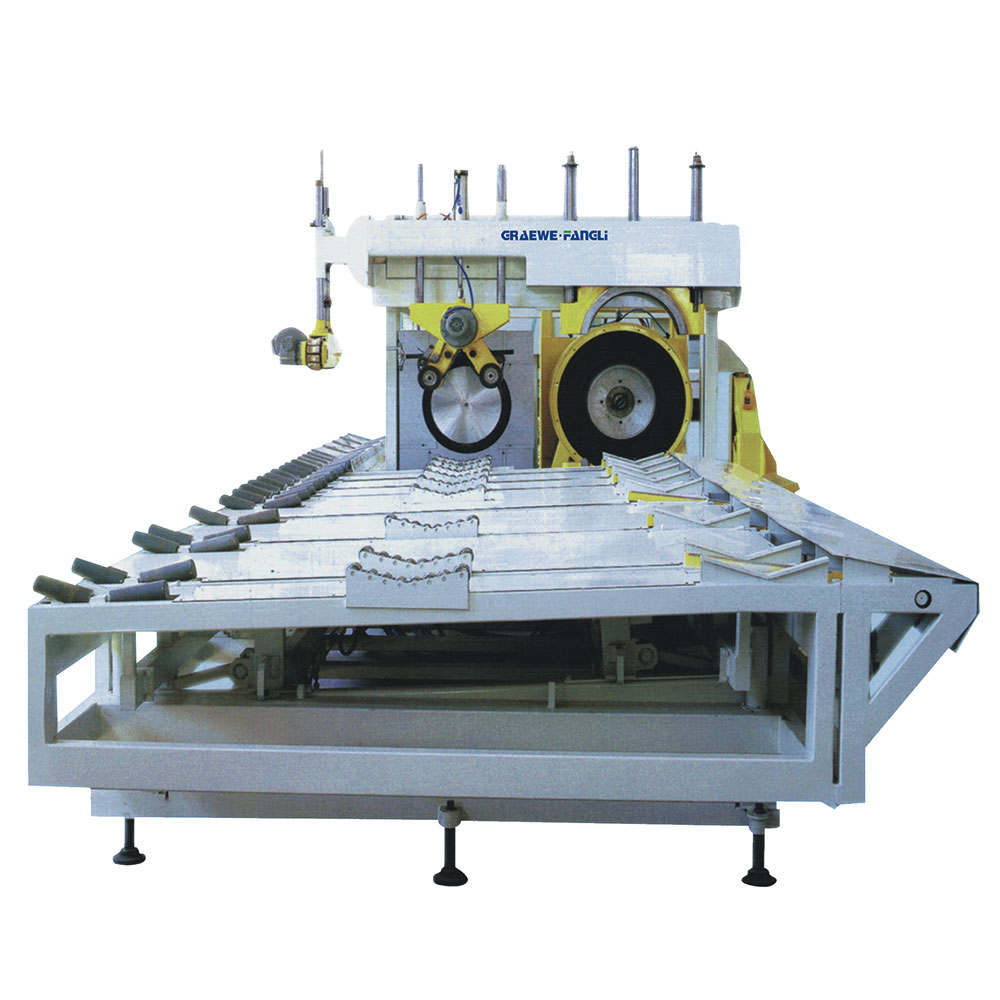

Belling Machine

Send Inquiry

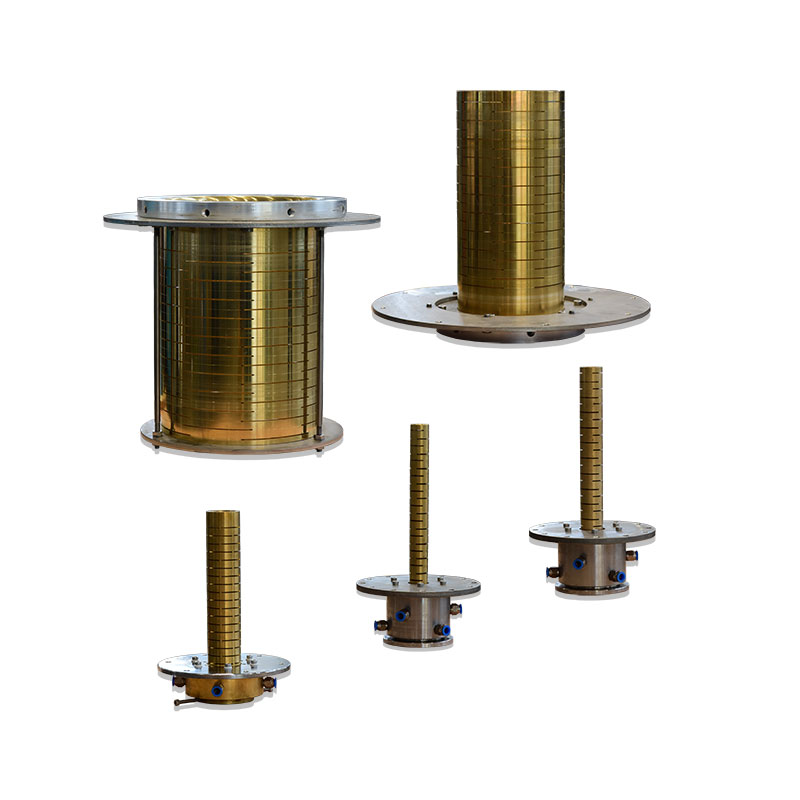

1. Belling Machine Introduction

The Pipe Belling Machine is applicable to the belling of UPVC (PVC-UH) plastic pipes. It can be used in combination with the plastic pipe production line or a stand-alone machine. The equipment is mainly composed of a feeding traction mechanism,a heating mechanism,a flared mechanism (including flared die), and a support frame. The equipment has high degree of automation, stable and reliable performance and convenient operation;the internal inflation pressure is shaped and the wall thickness is uniform; The belling can be different according to the plasticity of the material. The belling die can be expanded first and then casing, or first casing and then expansion. It has strong process adaptability, smooth flaring and obvious steps, consistent and intact size.

2.Belling Machine Parameter (Specification)

|

Model |

Pipe OD Range( mm ) |

Heating Power (kW) |

Total Power (kW) |

Cooling type |

Center Height ( mm ) |

|

SGK63-2 (double-pipe) |

2×Ф20~Ф63 |

4 |

5.6 |

Air Cooling |

1000 |

|

SGK250 |

Ф50~Ф250 |

7.2 |

12.5 |

1000 |

|

|

SGK450 |

Ф160~Ф400 |

15.6 |

22 |

Water Cooling |

1100 |

|

SGK630 |

Ф315~Ф630 |

25.4 |

36.2 |

1100 |

Parameters are subject to change without prior notice

3.Belling Machine Feature And Application

·PLC control, fully automatic installation of sealing ring function

·Used for belling of UPVC (PVC-UH) plastic pipes

·Flat or R-shaped belling is available

·Small diameter pipes adopt air cooling

·Large diameter pipes adopt water cooling

·PVC-UH pipe is a plastic pipe belling machine with rubber ring fixed structure

4.Belling Machine Details