English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

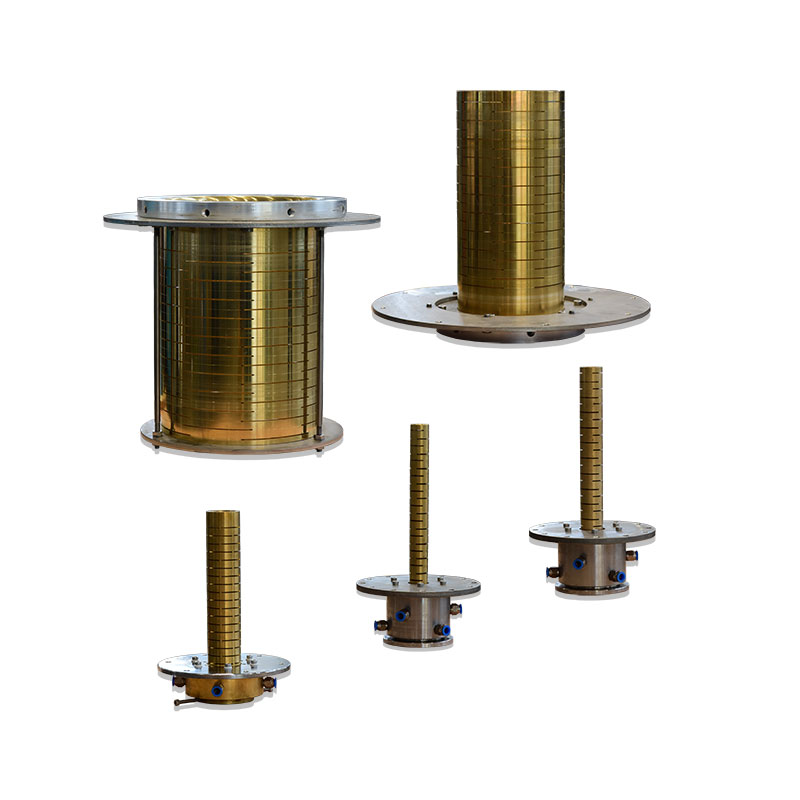

Spiral die-head

Spiral die-head introduces the newest German technology, and adopts the design-optimized internal spiral structure, to ensure the high quality and stable extrusion of various polyolefin raw materials.

Send Inquiry

1.Spiral die-head introduction

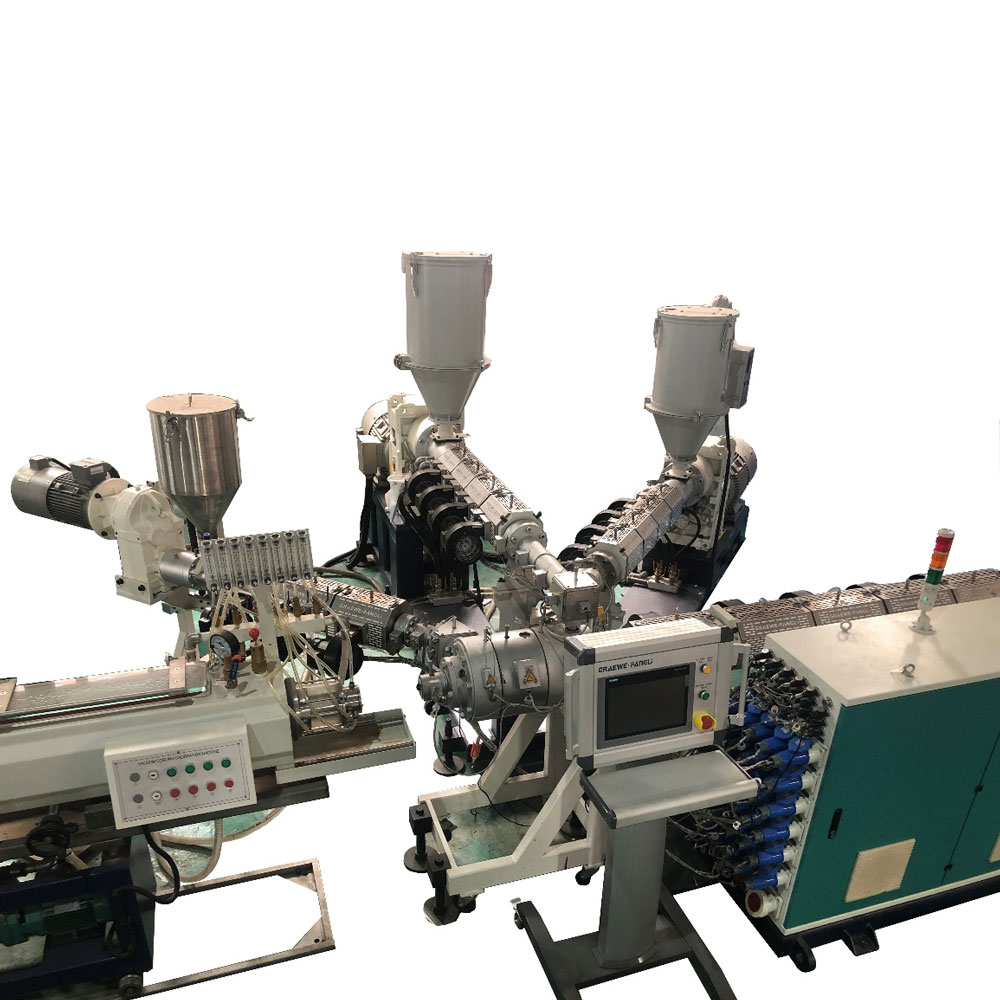

LXGM-G (high-end) series spiral polyolefin pipe extrusion die introduces the newest German technology, and adopts the design-optimized internal spiral structure, to ensure the high quality and stable extrusion of various polyolefin raw materials. The pipe inner wall cooling device is equipped for the specification above Ф 160 (including), and the whole series adopts modular and universal design. Each specification has single-layer and two-layer, three-layer composite structure. The whole series adopts high-end configuration of Fangli brand.

Features:

- Suitable for the stable extrusion of raw materials like HDPE/ MDPE, PP/ PP-R, PB, PE-RT;

- Accurate temperature control, low melt temperature;

- Low inner stress of the pipe;

- The color change time of extrusion with different color raw materials is less;

- Optimized die design to improve the appearance quality of pipes;

- Equipped with pipe inner wall cooling device;

- Conform to CE standard design;

2.Product parameter

|

Model |

LXGM63G |

LXGM160G |

LXGM250G |

LXGM315G |

LXGM450G |

LXGM630G |

LXGM800G |

LXGM1200G |

LXGM1600G |

LXGM2000G |

|

Production |

Ф16 |

Ф20 |

Ф50 |

Ф75 |

Ф90 |

Ф160 |

Ф315 |

Ф500 |

Ф710 |

Ф1000 |

|

Total power |

7 |

16 |

26 |

35 |

43 |

67 |

98 |

116 |

167 |

246 |

|

Mold core |

NO |

NO |

NO |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

Pipe inner |

NO |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

FLSJ45-36 |

300 |

|

|

|

|

|

|

|

|

|

|

FLSJ60-36 |

450 |

450 |

|

|

|

|

|

|

|

|

|

FLSJ75-36 |

|

600 |

600 |

600 |

600 |

|

|

|

|

|

|

FLSJ90-36 |

|

|

900 |

900 |

900 |

900 |

|

|

|

|

|

FLSJ120-36 |

|

|

|

|

1400 |

1400 |

1400 |

|

|

|

|

FLSJ150-36 |

|

|

|

|

|

|

1600 |

1600 |

2000 |

2000 |

Parameters are subject to change without prior notice

3.Product details