English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

Vacuum Calibration Tank

Send Inquiry

1.Vacuum calibration tank introduction

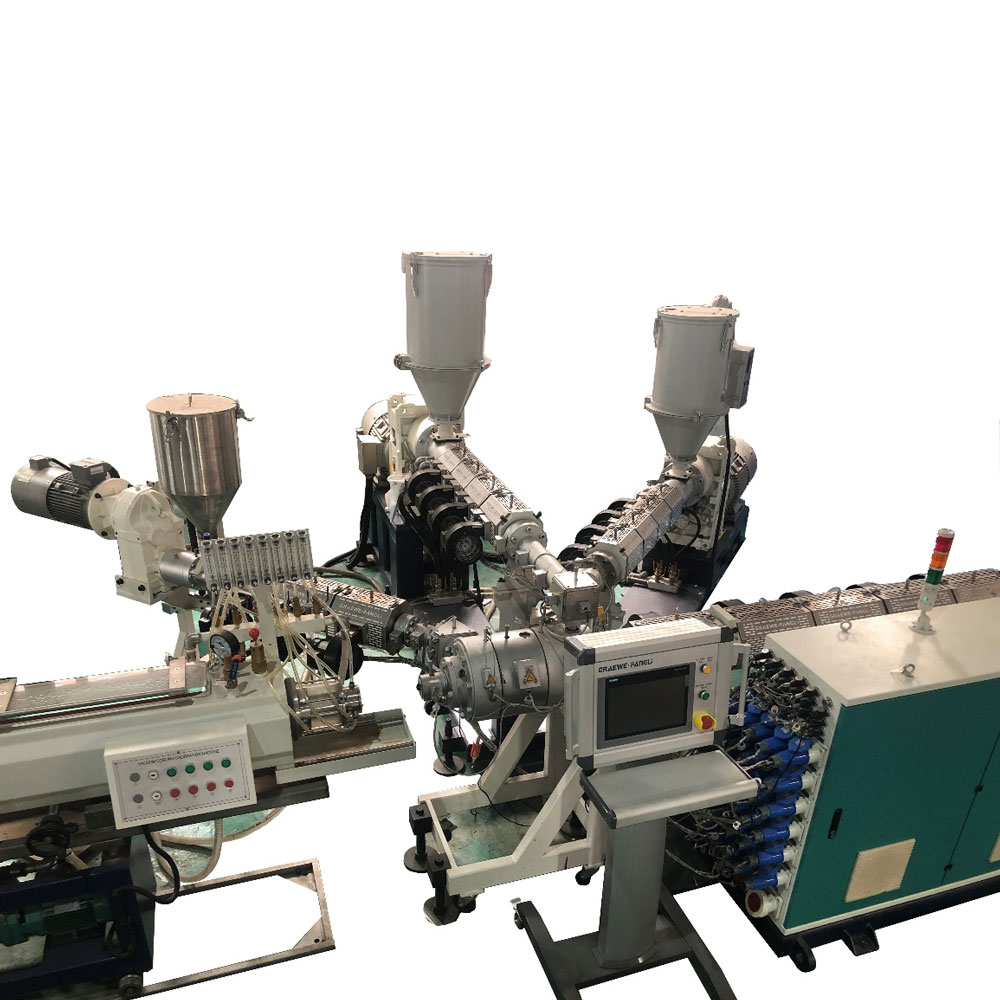

S (standard) series pipe vacuum shaping machine

- Adopt Fangli brand optimization configuration;

- 304 stainless steel tank and tempered glass cover door;

- Adopt transparent stainless steel float ball water level gauge to control and detect water level;

- Large diameter pipe adopts half moon plate support pipe;

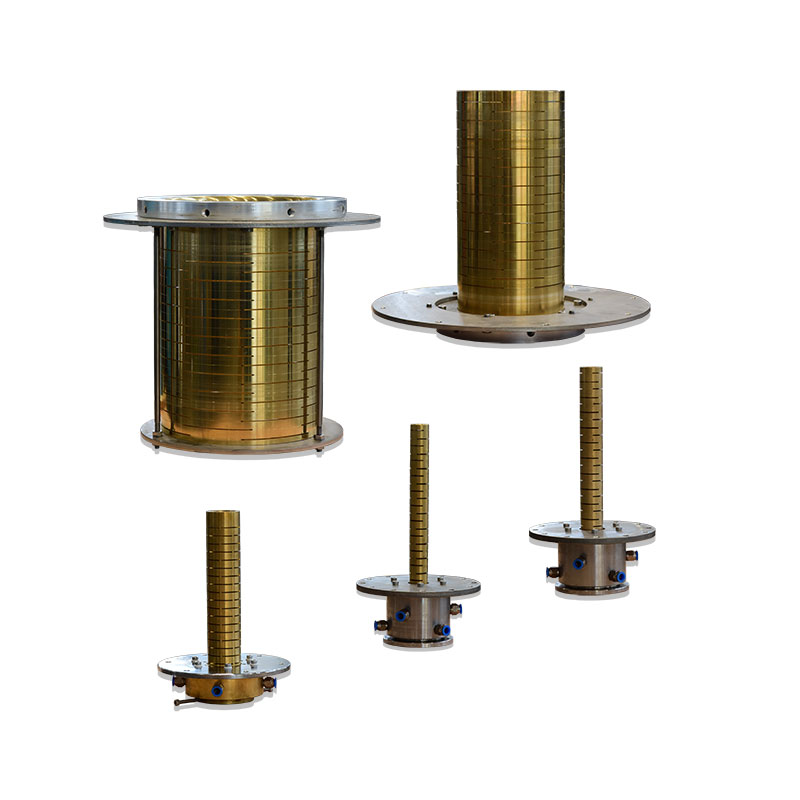

- Configured with sizing sleeve water distributor;

- With remote control function of tractor;

- Equipped with large diameter Y-type plastic filter;

- Adopt convex rubber seal.

G (high-end) series pipe vacuum shaping machine

- Adopt Fangli brand optimization configuration;

- 8500-11500 length 304 stainless steel thickened vacuum tank;

- Newly optimized design of stainless steel pipe;

- With remote control function of tractor;

- Use plastic bucket filter and angle seat solenoid valve;

- Adopt transparent stainless steel float ball water level gauge to control and detect water level;

- Adopt convex rubber seal and use new type water pump;

- Immersion bath and spray dual-purpose structure and water sealing device are adopted below 63 (including) specifications;

- Tempered glass visual door cover is used for specifications below 450 (including);

- Conform to CE standard design.

U (North American high-end) series pipe vacuum shaping machine

- Adopt GRAEWE FANGLI brand North American high-end configuration;

- 8500-11500 length 304 stainless steel thickened vacuum tank;

- Newly optimized design of stainless steel pipe;

- With remote control function of tractor;

- Use plastic bucket filter and angle seat solenoid valve;

- Adopt transparent stainless steel float ball water level gauge to control and detect water level;

- Adopt convex rubber seal and use new type water pump;

- Immersion bath and spray dual-purpose structure and water sealing device are adopted below 63 (including) specifications;

- Tempered glass visual door cover is used for specifications below 450 (including);

- Equipped with independent circulating heat exchange device to realize the cooling water in the tank being clean and stable;

- Conform to UL standard design;

- Developed and manufactured according to North American standard.

2.Product parameter

S (standard) series pipe vacuum shaping machine

|

Model |

Shaped pipe range |

shaping |

Number of vacuum chambers |

Center height |

Overall dimension |

|

ZD2-32S |

Ф12~Ф32 |

8500 |

2 |

1000 |

8500×300×1200 |

|

ZD2-63S |

Ф16~Ф63 |

8500 |

2 |

1000 |

8500×400×1360 |

|

ZD2-160S |

Ф20~Ф160 |

8500 |

2 |

1000 |

8500×500×1400 |

|

ZD2-250S |

Ф50~Ф250 |

8500 |

2 |

1000 |

8500×600×1500 |

|

ZD2-315S |

Ф75~Ф315 |

8500 |

2 |

1000 |

8500×700×1560 |

|

ZD2-450S |

Ф90~Ф450 |

8500 |

2 |

1100 |

8500×800×1600 |

|

ZD2-630S |

Ф160~Ф630 |

8500 |

2 |

1100 |

8500×900×1700 |

|

ZD2-800S |

Ф315~Ф800 |

8500 |

2 |

1200 |

8500×1900×2100 |

|

ZD2-1000S |

Ф400~Ф1000 |

11500 |

2 |

1400 |

11500×2200×2300 |

|

ZD2-1200S |

Ф500~Ф1200 |

11500 |

2 |

1600 |

11500×2400×2800 |

|

ZD2-1600S |

Ф710~Ф1600 |

11500 |

2 |

1800 |

11500×2700×3100 |

G (high-end) series pipe vacuum shaping machine

|

Model |

Shaped pipe range |

shaping |

Number of vacuum chambers |

Center height |

Overall dimension |

|

ZD2-32G |

Ф12~Ф32 |

8500 |

2 |

1000 |

8500×300×1200 |

|

ZD2-63G |

Ф16~Ф63 |

8500 |

2 |

1000 |

8500×400×1360 |

|

ZD2-160G |

Ф20~Ф160 |

8500 |

2 |

1000 |

8500×500×1400 |

|

ZD2-250G |

Ф50~Ф250 |

8500 |

2 |

1000 |

8500×600×1500 |

|

ZD2-315G |

Ф75~Ф315 |

8500 |

2 |

1000 |

8500×700×1560 |

|

ZD2-450G |

Ф90~Ф450 |

8500 |

2 |

1100 |

8500×800×1600 |

|

ZD2-630G |

Ф160~Ф630 |

8500 |

2 |

1100 |

8500×900×1700 |

|

ZD2-800G |

Ф315~Ф800 |

8500 |

2 |

1200 |

8500×1900×2100 |

|

ZD2-1000G |

Ф400~Ф1000 |

11500 |

2 |

1400 |

11500×2200×2300 |

|

ZD2-1200G |

Ф500~Ф1200 |

11500 |

2 |

1600 |

11500×2400×2800 |

|

ZD2-1600G |

Ф710~Ф1600 |

11500 |

2 |

1800 |

11500×2700×3100 |

U (North American high-end) series pipe vacuum shaping machine

|

Model |

Shaped pipe range |

shaping |

Number of vacuum chambers |

Center height |

Overall dimension |

|

ZD2-32U |

Ф12~Ф32 |

8500 |

2 |

1000 |

8500×300×1200 |

|

ZD2-63U |

Ф16~Ф63 |

8500 |

2 |

1000 |

8500×400×1360 |

|

ZD2-160U |

Ф20~Ф160 |

8500 |

2 |

1000 |

8500×500×1400 |

|

ZD2-250U |

Ф50~Ф250 |

8500 |

2 |

1000 |

8500×600×1500 |

|

ZD2-315U |

Ф75~Ф315 |

8500 |

2 |

1000 |

8500×700×1560 |

|

ZD2-450U |

Ф90~Ф450 |

8500 |

2 |

1100 |

8500×800×1600 |

|

ZD2-630U |

Ф160~Ф630 |

8500 |

2 |

1100 |

8500×900×1700 |

|

ZD2-800U |

Ф315~Ф800 |

8500 |

2 |

1200 |

8500×1900×2100 |

|

ZD2-1000U |

Ф400~Ф1000 |

11500 |

2 |

1400 |

11500×2200×2300 |

|

ZD2-1200U |

Ф500~Ф1200 |

11500 |

2 |

1600 |

11500×2400×2800 |

|

ZD2-1600U |

Ф710~Ф1600 |

11500 |

2 |

1800 |

11500×2700×3100 |

Parameters are subject to change without prior notice

3.Product details