English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

Industry Knowledge

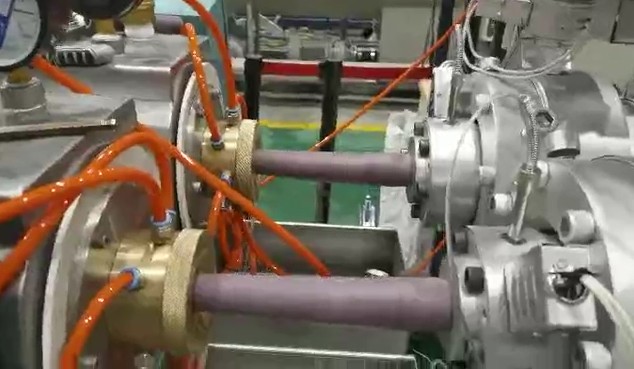

PPR Copper Liner Reinforced Composite Pipe

The utility model relates to a composite pipe of copolypropylene plastic and copper metal pipe, which comprises a copper pipe, a PPR plastic and an adhesive layer and an anticopper agent. Adhesives, anti-copper agent layer is arranged between the copper tube and PPR plastic tube layer, and the one-t......

Read MoreThe characteristics of PPR pipe extrusion production line

PPR pipe extrusion production line is used to produce single-layer solid plastic pipes with polyethylene, polypropylene and heat-resistant polyethylene, which are widely used at present. It is widely used in the fields of drinking water, gas, hot water and heating for urban residents, and fully meet......

Read MoreHow to maintain compound material pipe production line

As one of the common plastic machines, the composite pipe production line needs to be regularly maintained, which should also be operated according to certain procedures and the relevant requirements of the corresponding equipment safety technical performance. This is conducive to the operation of e......

Read MoreWhat are the advantages of PPR composite pipe production line?

PPR pipe has moderate price, stable performance, heat insulation, corrosion resistance, smooth inner wall without scaling, safe and reliable pipeline system without penetration, and its service life can reach 50 years. However, due to the high construction technology requirements, special tools and ......

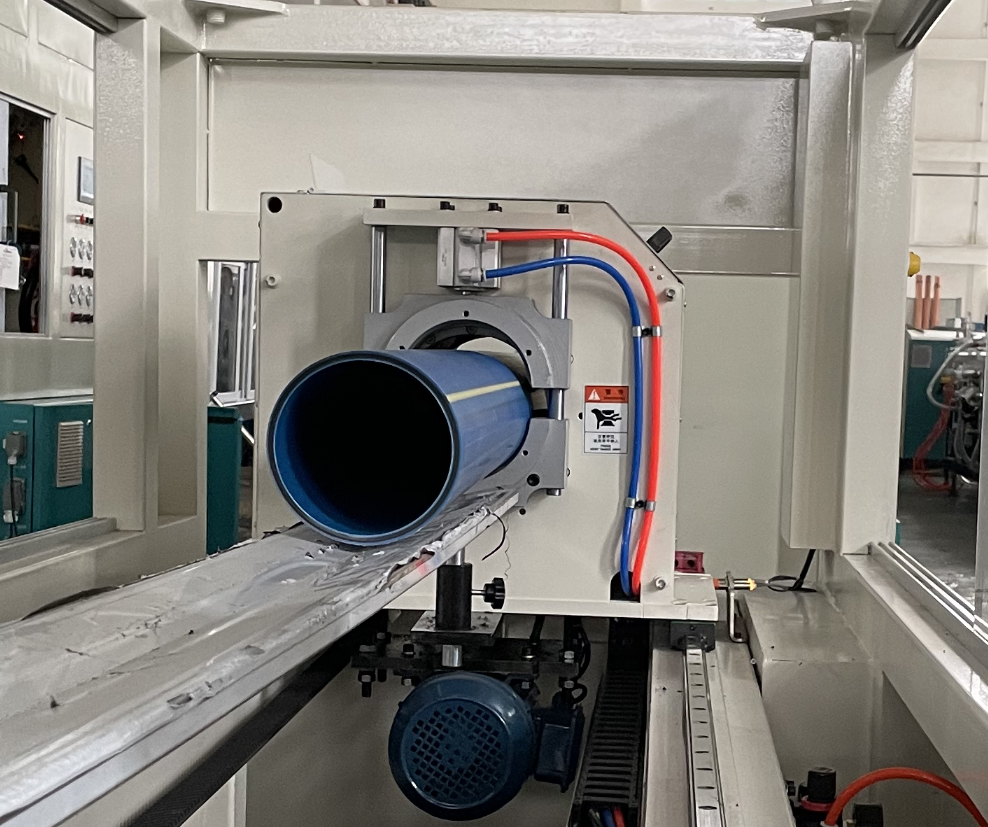

Read MoreDustless Ring Cutting Machine

The dust-free ring cutting machine for plastic pipes is independently developed by Ningbo Fangli Technology Co., Ltd. after continuous innovation and improvement, it is quite mature. At the same time, it adds the chamfering function, which has the advantages of low noise, less dust, energy conservat......

Read MoreSelection of heating and cooling methods for plastic extruder barrel

Heating and cooling are necessary conditions for plastic extrusion. In order to extrude plastics within the temperature range required by other processing technologies, the temperature of materials in the barrel of the plastic extruder is constantly adjusted by heating or cooling.

Read More