English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

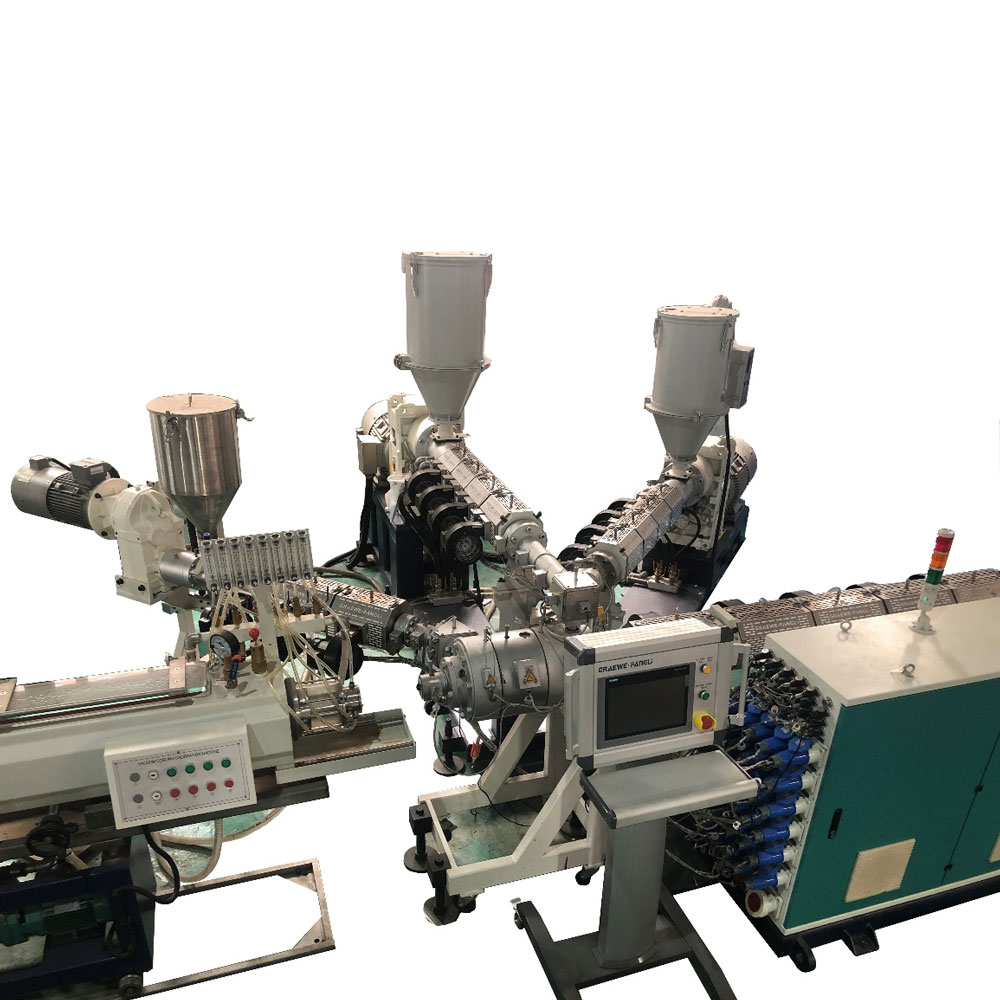

RTP Composite Pipe Extrusion Line

RTP composite pipe extrusion line introduces the newest technology from America, featuring corrosion resistance, high pressure resistance, temperature resistance and heat preservation, strong conveying capacity, good flexibility, coiling, less joints, good sanitary performance, long service life and high cost performance, etc. it is widely used in the transportation field of oil, natural gas and other mediums.

Send Inquiry

1.RTP composite pipe extrusion line introduction

RTP-S non-metal wire reinforced thermoplastic flexible composite pipe equipment introduces the newest technology from America. The high-end G type adopts EU standard and the North America high-end U type adopts North American standard. The whole series are configured according to GRAEWE FANGLI brand, specially applied to RTP non-metal wire reinforced thermoplastic flexible composite pipe equipment. The configuration is composed of three parts, including inner layer plastic pipe equipment unit, intermediate layer non metallic wire reinforced winding equipment unit and outer layer HDPE coating equipment unit, featuring high efficiency, high speed, high automation and energy saving, etc., being an ideal equipment for producing RTP non-metal wire reinforced thermoplastic flexible composite pipe. The produced RTP non-metal wire reinforced thermoplastic flexible composite pipe is a new type of pipe combining the advantages of thermoplastic, such as good flexibility, corrosion resistance and coiling, and the high strength of non-metallic wire reinforced material, mostly adopting three-layer structure, including inner lining layer, middle non-metallic belt reinforcing layer and outer covering protective layer. It has been successfully applied to the media transportation field in oil and gas, etc, such as oil collection, natural gas collection, water injection in oil and gas wells and oil and gas transportation, etc., with the advantages of corrosion resistance, high pressure resistance (maximum pressure up to 25MPa), temperature resistance and heat preservation, strong conveying capacity, good flexibility, coiling, less joints, good sanitary performance, long service life and high cost performance. In these fields, it has obvious advantages over simple steel pipe and plastic pipe (steel pipe is easy to corrode, and plastic pipe has insufficient strength and pressure bearing capacity).

2.Product parameter

|

Model |

Production pipe range (mm) |

Production pipe speed(m/min) |

Overall dimension( m ) |

Control system |

|

Finished pipe OD |

Finished pipe |

|||

|

RTP250G-S |

Φ50~Φ250 |

0.3~6 |

74×15×5.5 |

Controlled by program computer |

|

RTP250U-S |

Φ50~Φ250 |

0.3~6 |

74×15×5.5 |

3.Product details