English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

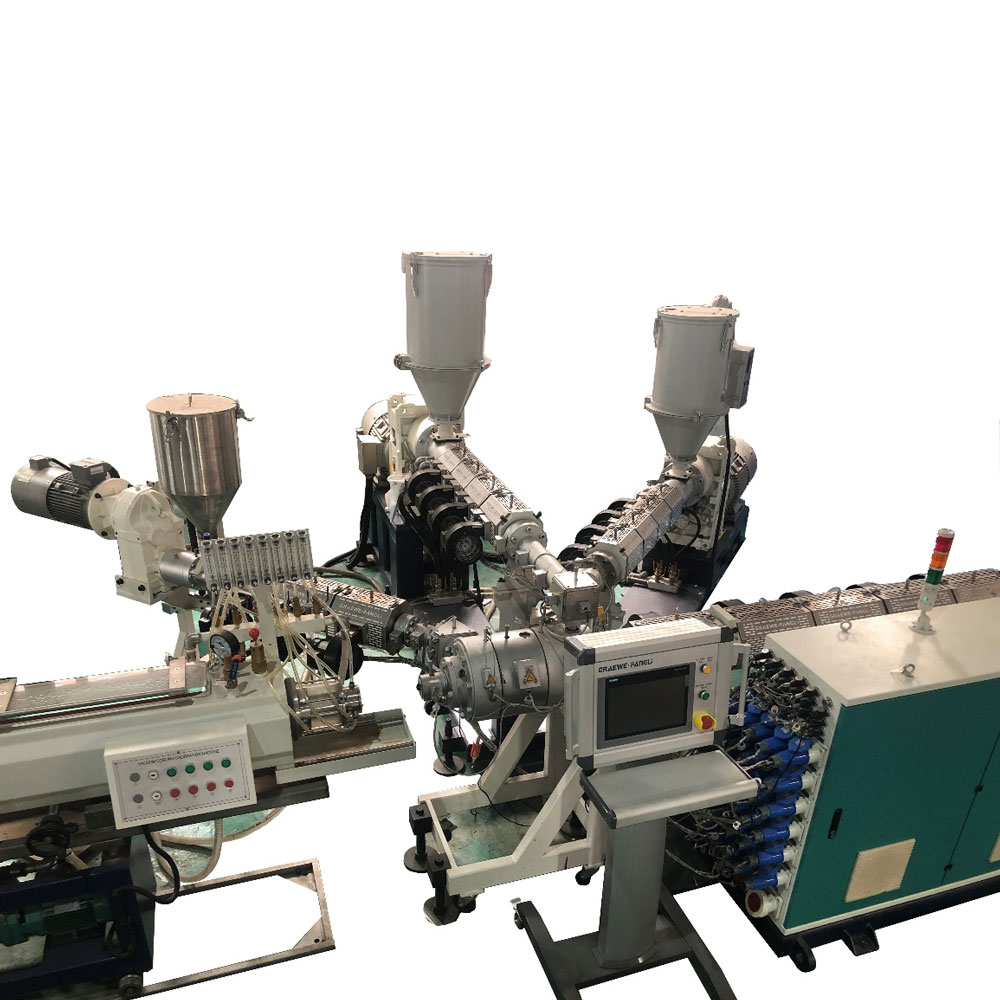

PE Pipe Extrusion Line

PE pipe extrusion line can realize high efficient and high speed extrusion, with the advantages of beautiful appearance, high automation degree, stable and reliable production. It has won popularity from the users for its European machine’s performance and domestic machine’s price. This equipment can also produce agricultural irrigation, heat preservation pipe, external protection pipe and other thin-wall pipes.

Send Inquiry

1.PE pipe extrusion line introduction

S (standard) series extrusion equipment is a new type pipe extrusion equipment successfully designed by our company on the basis of absorbing the European advanced technologies, which is suitable for the high speed extrusion of PE, PP, PB, PE-RT polyolefin pipes. This equipment is equipped with 36:1 extra long L/D ratio extruder, with the advantages of chip free cutting, high efficiency and high speed, beautiful appearance, high automation degree, stable and reliable production. It has won the popularity from the customers for its world class performance but with lower price, and it also can provide large diameter inner and outer layer composite and multi-layer composite pipes, which is the best choice for replacing the imported equipment. Our company has successfully researched and developed the pipe extrusion equipment with the largest diameter of Ф2500mm according to the market needs. Meanwhile, this kind of equipment can produce agricultural irrigation, heat preservation pipe, external protection pipe and other thin-wall pipes.

G (high-end) series extrusion equipment is our company’s newest PO pipe solutions, equipped with 36-40 super length diameter ratio extruder, with the advantages of servo traction control, chip free circular cutting, high efficiency, high speed, high automation, energy saving and protection. Our company has successfully researched and developed the pipe extrusion equipment with the largest diameter of Ф2500mm according to the market needs. In addition to the conventional pipe production, it can also satisfy many special requirements such as super thick wall pipe and multi-layer composite pipe according to different configuration schemes.

U (North American high-end) series extrusion equipment is the latest series of products developed and manufactured by our company according to the North American standard high-end configuration, adopting the latest European advanced technology, aiming at the demand and operation habits of the North American market. It is the latest PO pipe solution in the North American market, equipped with 36-40 super long diameter ratio extruder, European brand servo traction control and heavy duty chip free circular cutting. It has the advantages of high efficiency, high speed, high automation, energy saving and environmental protection. According to the North American market demand, our company has successfully developed a complete set of pipe extrusion equipment with the maximum diameter of Ф 2500mm. In addition to the conventional pipe production, it can meet various special requirements such as super thick wall pipe and multi-layer composite pipe according to different configuration schemes.

2.PE pipe extrusion line parameter

S (standard) series extrusion equipment

|

Model |

Production pipe range |

Production Output |

Production pipe speed |

Center height |

Overall dimension |

Control system |

|

PE32S-2 |

2×Φ16~Ф32 |

400~450 |

2×1.5~35 |

1000 |

45×3.8×1.8 |

Program |

|

PE63S-2 |

2×Φ16~Ф63 |

400~450 |

2×1.0~25 |

1000 |

48×3.8×1.9 |

|

|

PE63S |

Ф16~Ф63 |

400~450 |

1.5~30 |

1000 |

45×3.1×1.9 |

|

|

PE160S |

Ф20~Ф160 |

400~450 |

1.0~20 |

1000 |

38×3.2×2.0 |

|

|

PE250S |

Ф50~Ф250 |

550~600 |

0.5~10 |

1000 |

48×3.3×2.2 |

|

|

PE315S |

Ф75~Ф315 |

550~600 |

0.2~6.0 |

1000 |

50×3.4×2.3 |

|

|

PE450S |

Ф90~Ф450 |

800~900 |

0.2~5.0 |

1100 |

52×3.5×2.7 |

|

|

PE630S |

Ф160~Ф630 |

800~900 |

0.1~2.0 |

1100 |

58×3.6×2.8 |

|

|

PE800S |

Ф315~Ф800 |

1250~1400 |

0.05~1.5 |

1200 |

62×3.6×3 |

|

|

PE1000S |

Ф400~Ф1000 |

1250~1400 |

0.03~1.0 |

1400 |

65×3.6×3 |

|

|

PE1200S |

Ф500~Ф1200 |

1500~1600 |

0.03~0.6 |

1600 |

75×3.8×3 |

|

|

PE1600S |

Ф710~Ф1600 |

1500~1600 |

0.02~0.4 |

1800 |

80×4×3.2 |

|

|

PE2000S |

Ф1000~Ф2000 |

1800~2000 |

0.02~0.3 |

2200 |

85×4.5×4.8 |

|

|

PE2500S |

Ф1400~Ф2500 |

1800~2000 |

0.01~0.2 |

3000 |

88×4.8×5.0 |

G (high-end) series PE polyethylene pipe high speed high efficient extrusion equipment

|

Model |

Production pipe range |

Production Output |

Production pipe speed |

Center height |

Overall dimension |

Control system |

|

PE32G-2 |

2×Φ16~Ф32 |

400~450 |

2×1.5~35 |

1000 |

45×3.8×1.8 |

Program |

|

PE63G-2 |

2×Φ16~Ф63 |

400~450 |

2×1.0~25 |

1000 |

48×3.8×1.9 |

|

|

PE63G |

Ф16~Ф63 |

400~450 |

1.5~30 |

1000 |

45×3.1×1.9 |

|

|

PE160G |

Ф20~Ф160 |

400~450 |

1.0~20 |

1000 |

38×3.2×2.0 |

|

|

PE250G |

Ф50~Ф250 |

550~600 |

0.5~10 |

1000 |

48×3.3×2.2 |

|

|

PE315G |

Ф75~Ф315 |

550~600 |

0.2~6.0 |

1000 |

50×3.4×2.3 |

|

|

PE450G |

Ф90~Ф450 |

800~900 |

0.2~5.0 |

1100 |

52×3.5×2.7 |

|

|

PE630G |

Ф160~Ф630 |

1250~1400 |

0.1~3.0 |

1100 |

60×3.6×2.8 |

|

|

PE800G |

Ф315~Ф800 |

1250~1400 |

0.05~1.5 |

1200 |

62×3.6×3 |

|

|

PE1000G |

Ф400~Ф1000 |

1500~1600 |

0.03~1.0 |

1400 |

67×3.6×3 |

|

|

PE1200G |

Ф500~Ф1200 |

1500~1600 |

0.03~0.6 |

1600 |

75×3.8×3 |

|

|

PE1600G |

Ф710~Ф1600 |

1500~1600 |

0.02~0.4 |

1800 |

80×4×3.2 |

|

|

PE2000G |

Ф1000~Ф2000 |

1800~2000 |

0.02~0.3 |

2200 |

85×4.5×4.8 |

|

|

PE2500G |

Ф1400~Ф2500 |

1800~2000 |

0.01~0.2 |

3000 |

88×4.8×5.0 |

U (North American high-end) series PE polyethylene pipe high speed high efficient extrusion equipment

|

Model |

Production pipe range |

Production Output |

Production pipe speed |

Center height |

Overall dimension |

Control system |

|

PE32U-2 |

2×Φ16~Ф32 |

400~450 |

2×1.5~35 |

1000 |

45×3.8×1.8 |

Program |

|

PE63U-2 |

2×Φ16~Ф63 |

400~450 |

2×1.0~25 |

1000 |

48×3.8×1.9 |

|

|

PE63U |

Ф16~Ф63 |

400~450 |

1.5~30 |

1000 |

45×3.1×1.9 |

|

|

PE160U |

Ф20~Ф160 |

400~450 |

1.0~20 |

1000 |

38×3.2×2.0 |

|

|

PE250U |

Ф50~Ф250 |

550~600 |

0.5~10 |

1000 |

48×3.3×2.2 |

|

|

PE315U |

Ф75~Ф315 |

550~600 |

0.2~6.0 |

1000 |

50×3.4×2.3 |

|

|

PE450U |

Ф90~Ф450 |

800~900 |

0.2~5.0 |

1100 |

52×3.5×2.7 |

|

|

PE630U |

Ф160~Ф630 |

1250~1400 |

0.1~3.0 |

1100 |

60×3.6×2.8 |

|

|

PE800U |

Ф315~Ф800 |

1250~1400 |

0.05~1.5 |

1200 |

62×3.6×3 |

|

|

PE1000U |

Ф400~Ф1000 |

1500~1600 |

0.03~1.0 |

1400 |

67×3.6×3 |

|

|

PE1200U |

Ф500~Ф1200 |

1500~1600 |

0.03~0.6 |

1600 |

75×3.8×3 |

|

|

PE1600U |

Ф710~Ф1600 |

1800~2000 |

0.02~0.5 |

1800 |

82×4×3.2 |

|

|

PE2000U |

Ф1000~Ф2000 |

1800~2000 |

0.02~0.3 |

2200 |

85×4.5×4.8 |

|

|

PE2500U |

Ф1400~Ф2500 |

1800~2000 |

0.01~0.2 |

3000 |

88×4.8×5.0 |

3.PE pipe extrusion line details