English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

News

How to choose cutting machine for pipe production in the extrusion line

The extruder production line can continuously produce plastic pipes. Because the pipe production is uninterrupted, and the pipe has a fixed length specified in the standard, in order to ensure the standard length of the pipe, we need to use the cutting machine as an auxiliary equipment to cut the pi......

Read MoreWhat kind of screw is a good screw

It is no exaggeration to say that the screw is the heart of the extruder. Its quality can determine the production capacity, plasticizing quality, solution temperature and power consumption of an extruder, which are related to the performance of a screw. Plasticizing quality refers to the quality of......

Read MorePrinciple of Counter Rotating Twin Screw Extruder

Twin screw extruder has the characteristics of forced conveying, short residence time, good exhaust performance, uniform mixing and low power. Twin screw extruder is mainly composed of two mutually meshing screws rotating in the barrel, forcing the material to shear and move forward.

Read MoreCan Increasing the Rotational Speed of the Main Machine of the Plastic Extruder Improve the Productivity of the Equipment?

After the plastic products manufacturers purchase the plastic extruder, in order to maximize the use efficiency of the extruder equipment, we hope to maximize the production capacity of the plastic extruder. In the case that the equipment can not be upgraded or transformed, we will improve the produ......

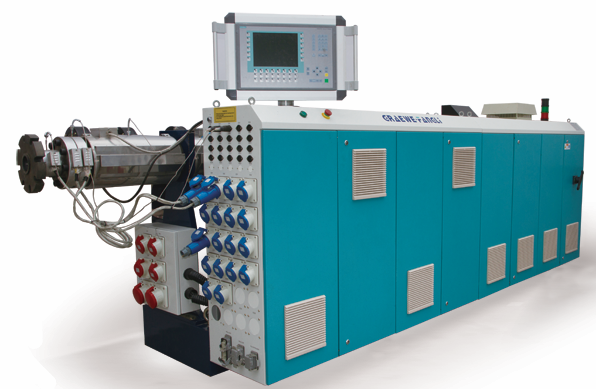

Read MoreFLSP Series Counter-rotating Parallel Twin-screw Extruder —The Choice of High-efficiency PVC Pipe Extrusion Production Line

In order to adapt to the market and meet the needs of domestic and foreign industries for PVC main equipment, Ningbo Fangli Technology Co., Ltd. has increased its R&D investment in FLSP series counter-rotating parallel twin-screw extruders since 2017, and achieved good results. Compared with the ori......

Read MoreThe basic principle of plastic pipe extrusion molding

The extrusion molding process of plastic pipe is divided into three stages I. Plasticization of raw materials. This process can make the solid materials turn into a uniform viscous fluid through the heating and mixing of the extruder; II. Forming. Under the function of extrusion parts of the extru......

Read More