English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

News

Composition and Function of PVC Pipe Extrusion Production Line

Here, we briefly introduce the composition and functions of PVC pipe extrusion production line as follows for your reference: I. Raw material mixing: PVC stabilizer, plasticizer, antioxidant and other auxiliary materials are successively added into the high-speed mixer according to proportion and......

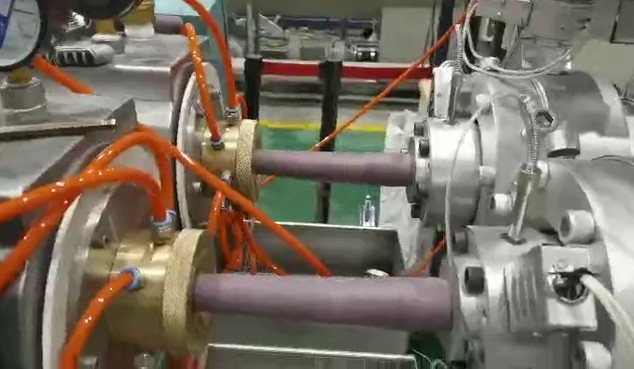

Read MoreExtruder for PVC-U Pipe Extrusion Line

Parallel twin-screw extruder and conical twin-screw extruder can be used to directly produce PVC-U pipe with dry powder. Due to the full engagement of two screws, a closed C-shaped chamber is formed in the twin-screw extruder. The two screws rotate outward in different directions to make the C-shape......

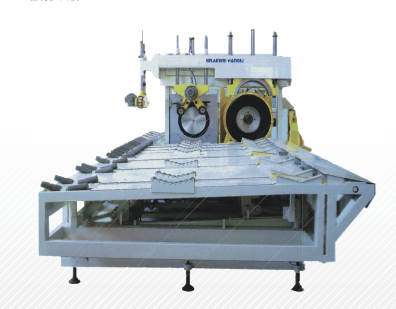

Read MoreAutomatic Belling Machine or will become a Popular Equipment?

The development of the social economy has stimulated all walks of life to move forward, for the current society, high efficiency, high production has become the production standards of enterprises. For the automatic belling machine production enterprises have gradually stepped into the automation of......

Read MoreTop tips for extrusion

Optimise tempering Self-optimising, closed-loop screw tempering for counter rotating twin screws affords more cooling effectiveness than oil tempering – and is free of maintenance. Internal screw tempering helps to widen the process window and increase screw output. It gives constant temperature pr......

Read MoreFive Points for Attention in PVC Pipe Production

In the production process, since PVC is a kind of heat sensitive material, even if heat stabilizer is added, it can only increase the decomposition temperature and prolong the stable time without decomposition, which requires strict control of PVC molding temperature. Especially for RPVC, since its ......

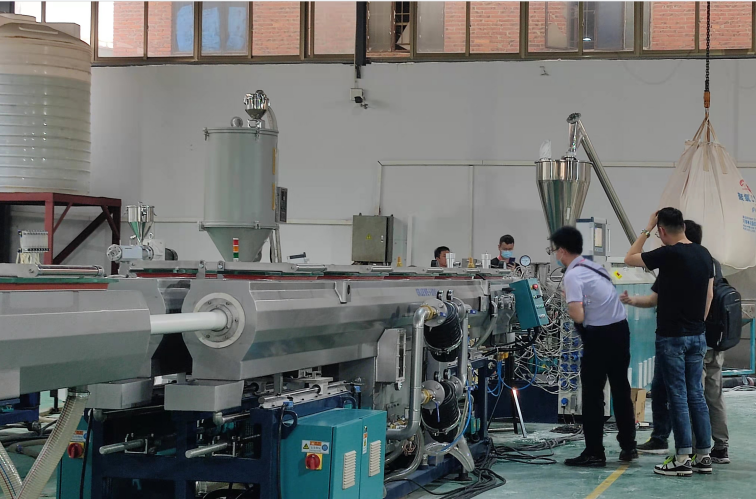

Read MorePE/PRR32-2 dual-pipe production line

A new type of PE/PPR dual-pipe extrusion line (model: PE 32-2; PPR 32-2) has been successfully developed by Ningbo Fangli Technology Co., Ltd. based on years’ R&D as well as production experience accumulated. The line is suitable for the production of PE/PPR pipe diameter range from 12mm to 32mm and......

Read More