English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

News

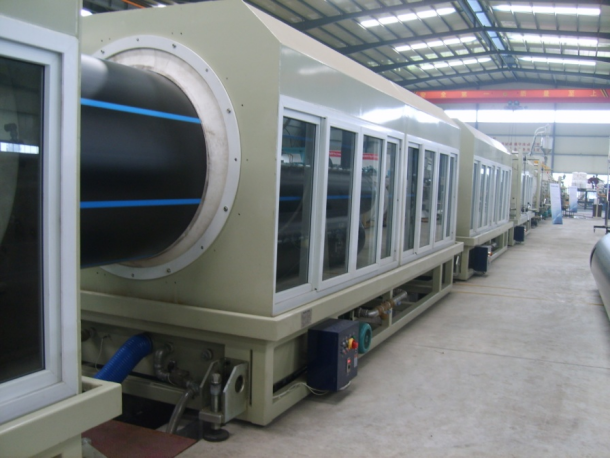

echnical characteristics and application scope of hollow wall winding pipe

The hollow wall winding pipe uses polyethylene as the raw material, which is a product advocated by the state to replace steel with plastic. The pipe is of hollow wall structure and fused into one, so that it has good impact resistance and pressure resistance. The hollow wall winding pipe has the fo......

Read MoreSteel skeleton plastic composite pipe

The Steel skeleton plastic composite pipe is a new type of improved steel frame plastic composite pipe. This new type of pipe is made of high-strength superplastic steel wire mesh skeleton and thermoplastic polyethylene as raw materials, steel wire winding mesh as the skeleton reinforcement of polye......

Read MoreWhat cross-section deformation problems will occur in plastic pipe produced by extruder

Modern plastic pipe industry mainly uses extruders for extrusion molding production. Plastic pipes are usually round. Different uses have certain requirements for the roundness of pipes. The cross-section deformation trend of plastic pipe produced by extruder production line is to a certain extent, ......

Read MoreMaintenance and repair of extruder reducer

The reducer is an important part of the pipe extrusion equipment. The following are the precautions for the maintenance and repair of the reducer: 1. After the machine is used for a period of time, a comprehensive inspection should be made to check the tightness of all screws.

Read MoreExtrusion process of plastic pipes

The extrusion process of plastic pipes is divided into three stages: 1. Plasticization of raw materials, that is, through the heating and mixing of the extruder, the solid raw materials become uniform viscous fluid. 2. Molding, that is, under the action of the extrusion parts of the extruder, th......

Read MoreNotes for Production Operation of Twin Screw Extruder

Here we prepared some notes for production operation of twin screw extruder are: 1.When the twin-screw extruder starts normal production, it is necessary to first check whether the inner seals of the barrel and hopper are the original sealed samples. If there is any change or damage, it is necess......

Read More