English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

Industry Knowledge

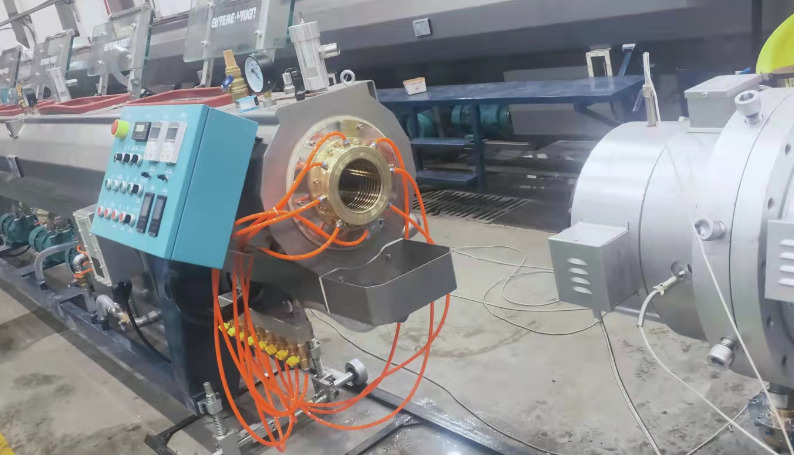

Design and Construction Principle of Screw of Plastic Extruder

Feeding area of plastic extruder: the fixed groove depth of screw groove, which is responsible for preheating, plastic solid conveying and extrusion. It must be ensured that the plastic starts to melt at the end of the feeding section - that is, it must be preheated to the melting point. The general......

Read MoreCalibration sleeve and its function

The calibration sleeve is a component that assists the cooling and shaping of plastic pipes in the extrusion production of plastic pipes. It is installed at the front end of the vacuum calibration machine. After the pipe comes out of the mold, it enters the vacuum tank and spray cooling tank for fur......

Read MoreType of extruder screws

A screw with excellent performance should not only have high output, but also have a plasticizing effect that meets the product performance and a good comprehensive performance of temperature, pressure and speed. Therefore, a variety of new screws have come out one after another, which greatly impro......

Read MoreMain parameters of the single screw extruder

Screw refers to the metal rod with screw groove that can rotate in the barrel of extruder or injection molding machine. Screw is the most important part of extruder to transport solid plastic, plasticized plastic and melt, which is often called the heart of extruder. Through the rotation of the scre......

Read MoreProblems and solutions of extruder in the production process of insulation pipe equipment

Plastic extrusion has always been an important link in the production process of insulation pipe equipment, which is not only related to speed but also to quality, and the extruder plays a decisive role in this link. Ningbo Fangli Technology Co., Ltd. has summarized a series of experience from theor......

Read More