English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

Industry Knowledge

Feasibility of Reinforced Thermoplastic Pipe for High Pressure Long distance Hydrogen Transmission Pipeline

In the modern vigorous development of global oil and natural gas, a major technological breakthrough in high-pressure long-distance pipeline transportation is the continuous development and expansion of applications of reinforced thermoplastic pipes, which show unique advantages, especially in parti......

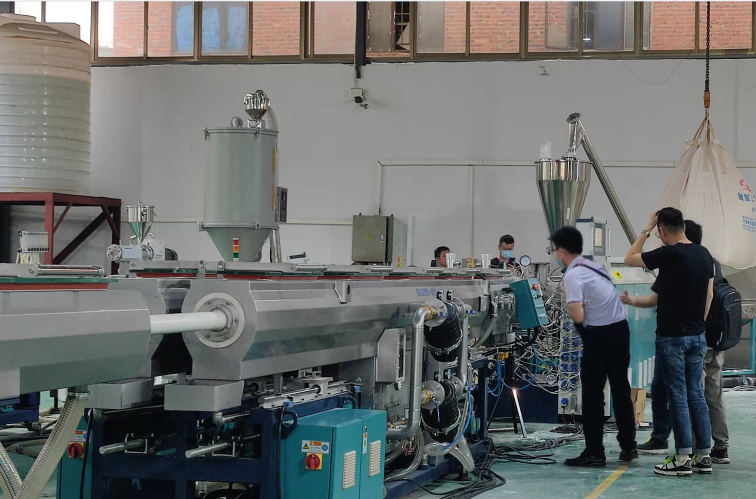

Read MoreIs the extruder screw often worn? There are these main reasons!

Screw extruder is the core equipment of plastic forming and blending modification. In the actual production process of blending modification, the screw of the extruder is in a harsh high pressure and high temperature environment, and bears huge friction and shear force. Due to the special working......

Read MorePerformance Characteristics of Various PVC-U Pipes

With the enhancement of people's awareness of environmental protection, the requirements for building water supply and drainage are higher and higher, and various new structural PVC-U pipes came into being. Its functions and characteristics are different.

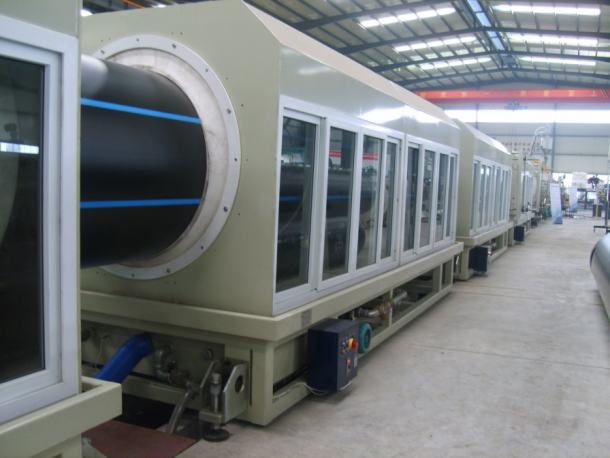

Read MoreApplication Prospect of Plastic Pipe Extrusion Equipment

The production process of plastic pipe extrusion should be selected according to the type and size of plastic pipe. Generally, plastic extruders are used to extrude products. However, plastic materials and types of plastic pipes are different, so the principle of molding in production is different. ......

Read MoreWhat to do when there is no vacuum in the production of PE three-layer co-extrusion pipe equipment

PE three-layer co-extrusion pipe equipment production line is a production and manufacturing line of plastic pipes using vacuum sizing technology. However, if the technology is not mature, the processing is rough, and the process is not refined, some unexpected failures may occur, such as no vacuum.......

Read MoreDeceleration principle of twin-screw extruder

In most extruders, the screw speed changes by adjusting the motor speed. The drive motor usually rotates at full speed of about 1750 rpm, which is too fast for an extruder screw. If it rotates at such a fast speed, too much friction heat will be generated, and the retention time of plastic is too sh......

Read More