English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

Industry Knowledge

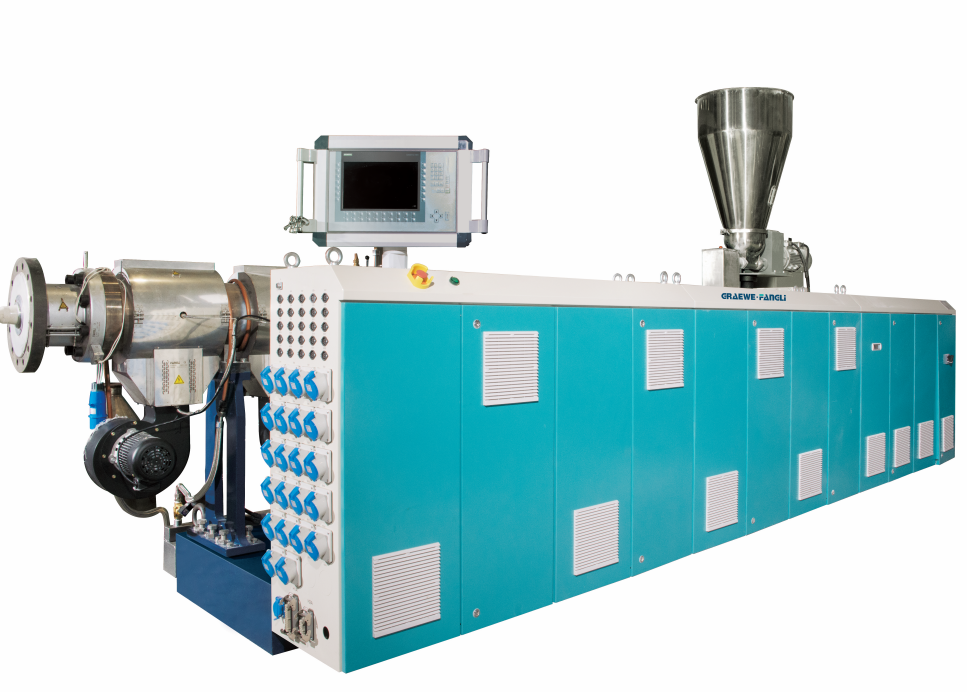

FLSP Series Counter-rotating Parallel Twin-screw Extruder —The Choice of High-efficiency PVC Pipe Extrusion Production Line

In order to adapt to the market and meet the needs of domestic and foreign industries for PVC main equipment, Ningbo Fangli Technology Co., Ltd. has increased its R&D investment in FLSP series counter-rotating parallel twin-screw extruders since 2017, and achieved good results. Compared with the ori......

Read MoreWays to Improve the Working Efficiency of Twin Screw Extruder

What are the ways to improve the working efficiency of the twin-screw extruder, increase the consumption efficiency, increase the free volume of the screw groove and increase the torque and speed, the following is a detailed introduction.

Read MoreFeatures of Twin Screw Extruder Gearbox

A new design of the gearbox transmission system of the twin-screw extruder. The output shaft transmission adopts a power split design, which doubles the torque transmitted by the output shaft, increases the carrying capacity of the whole machine by 50%, and increases the insurance coefficient by 30%......

Read MoreThe Structure Principle of Twin Screw Extruder

The basic mechanism of the extrusion process is simply a screw that rotates in the barrel and pushes the plastic forward. The screw structure is a slope or slope wound on the center layer, the purpose of which is to increase the pressure in order to overcome the greater resistance.

Read MoreThe Temperature Principle of Twin Screw Extruder

Extrudable plastics are thermoplastics, which melt when heated and solidify again when cooled. Therefore, heat is required during the extrusion process to ensure that the plastic can reach the melting temperature. So where does the heat of melting plastic come from?

Read More