English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

Industry Knowledge

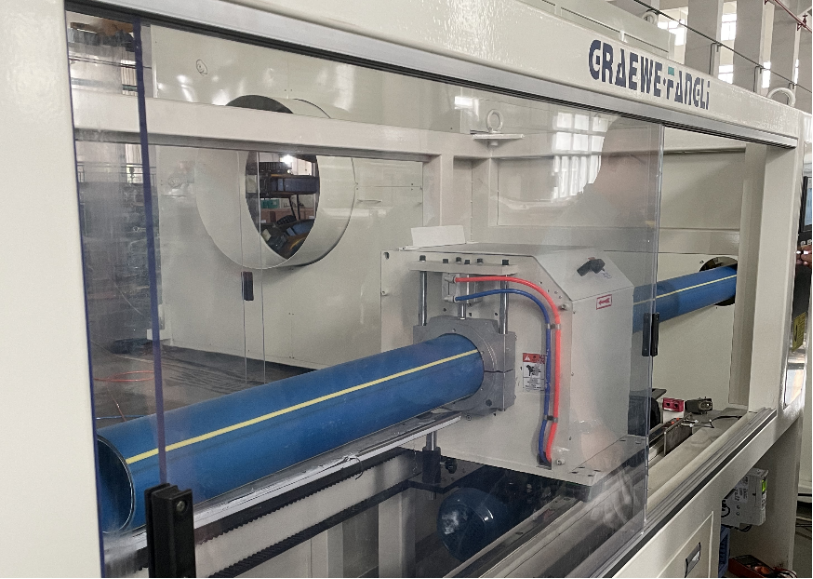

G Series PVC Two-Stand High Speed & High Efficiency Pipe Extrusion Line (PVC-U 75G-2)

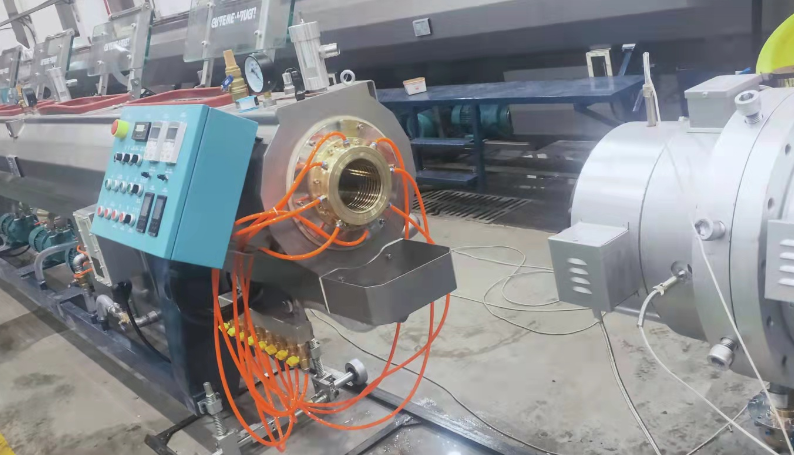

he process of PVC pipe production line Main production process: preparation of raw materials + additives → mixing → conveying and feeding → forced feeding → counter rotating parallel twin screw extruder → mold → sizing sleeve → spray vacuum calibration tank → spray or immersion cooling tank →crawle......

Read MoreThree-layer Composite PP Pipe Extrusion Line

Pipe has three layers to provide the highest mechanical performance: 1.External black PP layer provides excellent impact resistance and long-term UV protection; 2.Intermediate PP-MD layer provides high mechanical resistance and excellent sound proofing performance; 3.Internal layer low-friction, ......

Read MorePPR Copper Liner Reinforced Composite Pipe

The utility model relates to a composite pipe of copolypropylene plastic and copper metal pipe, which comprises a copper pipe, a PPR plastic and an adhesive layer and an anticopper agent. Adhesives, anti-copper agent layer is arranged between the copper tube and PPR plastic tube layer, and the one-t......

Read MoreCalibration sleeve and its function

The calibration sleeve is a component that assists the cooling and shaping of plastic pipes in the extrusion production of plastic pipes. It is installed at the front end of the vacuum calibration machine. After the pipe comes out of the mold, it enters the vacuum tank and spray cooling tank for fur......

Read MoreHow to Save Electricity and Better Maintenance Twin-Screw Extruder?

Twin-screw extruder is a kind of dispersion in which solid powder and liquid coexist and are mainly composed of solid phase, through forced way to make the basic partical of solid powder mutual bonding and increasing. And form a certain shape and particle size uniform, concentrated particle group.

Read More