English

English 简体中文

简体中文  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी

Industry Knowledge

Analysis on the Forming Quality of PVC Double Wall Corrugated Pipe Produced by Plastic Extruder

Plastic extruder will inevitably have some quality problems in the production of polyvinyl chloride (PVC) double wall corrugated pipe, in addition to the problems of equipment itself, there are still very cases of quality problems. We can ignore the problems caused by equipment, because generally, t......

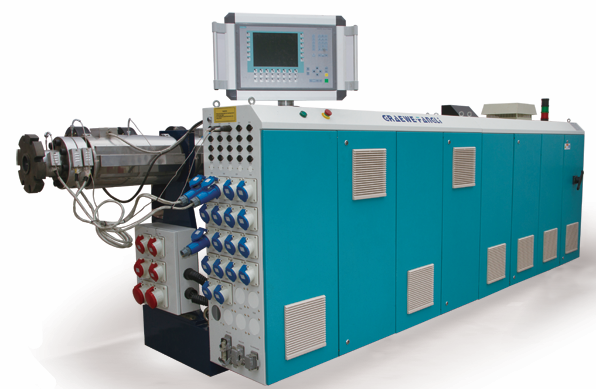

Read MorePrinciple and application scope of single screw extruder

In most extruders, the screw speed is changed by adjusting the motor speed. The drive motor usually rotates at a full speed of about 1750rpm, which is too fast for an extrusion screw. If it rotates at such a fast speed, too much friction heat will be generated, and the uniform and well stirred melt ......

Read MoreWhat is the function of the barrel? What are the characteristics of the structure?haracteristics of the structure?

The barrel includes a screw, which rotates in the barrel. When the screw rotates and the thread is pushed, the heat is transmitted to the material by heating outside the barrel. In addition, the volume of the thread is gradually reduced, so that the material is evenly mixed and plasticized into a mo......

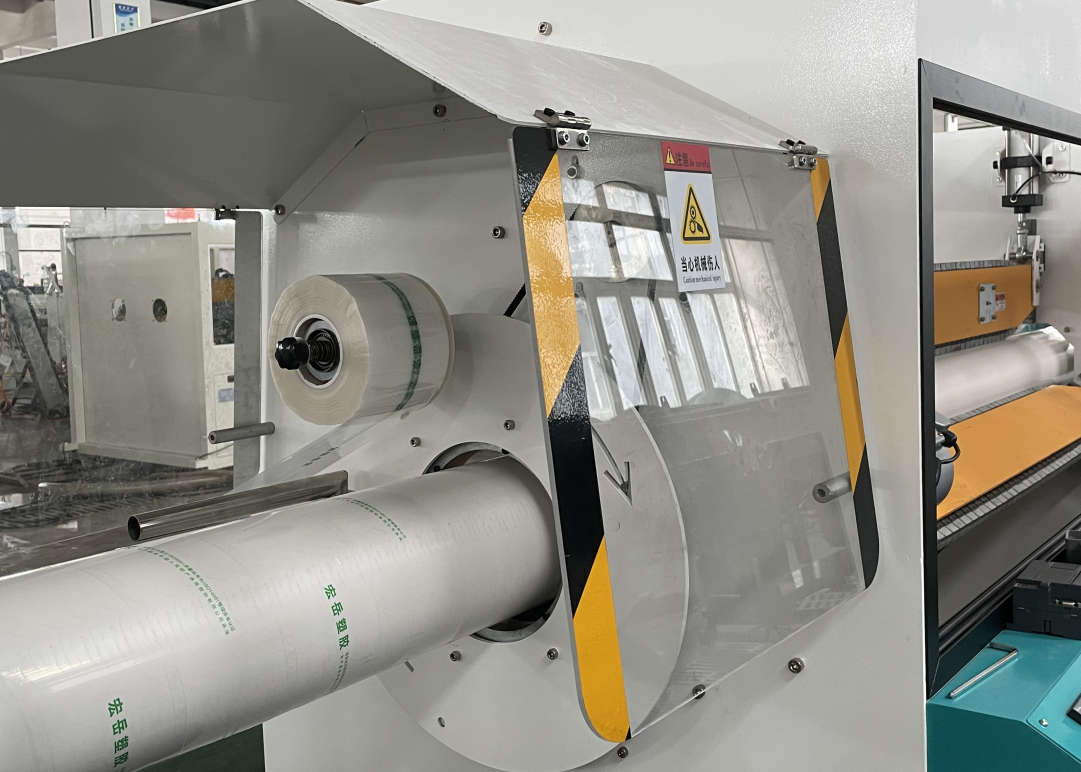

Read MoreCalibration sleeve and its function

The calibration sleeve is a component that assists the cooling and shaping of plastic pipes in the extrusion production of plastic pipes. It is installed at the front end of the vacuum calibration machine. After the pipe comes out of the mold, it enters the vacuum tank and spray cooling tank for fur......

Read MoreMaintenance of Single Screw Extruder

The maintenance of the extruder is divided into routine maintenance and regular maintenance: routine maintenance is a regular routine work, usually completed during start-up. The key is to clean the machine, lubricate the moving parts, fasten the loose threaded parts, and timely check and adjust the......

Read MorePVC Pipe & PVC Pipe Extrusion Line

PVC Pipe has good tensile and compressive strength, but its flexibility is better than other plastic pipe, excellent corrosion resistance, the cheapest price in all kinds of plastic pipe, but low temperature brittle adhesive, rubber ring socket flange connection, threaded connection for residential ......

Read More